Quickest Way To Face Tube & Pipe

Facing tube and pipe is an often overlooked part of the welding processes. A clean face is vital to creating a quality weld. Facing removes contaminants, squares the connections, and helps create a better weld without porosity or distortion. T+C Facing tools are engineered in Singapore and distributed by Morgan Industrial.

Learn How To Face Tube On The FM114

Tube and Pipe Facing Tools

FM-Micro Facing

The portable, battery-operated FM-Micro Facing Tool is designed to reach many stainless steel fittings and tube ends behind manifolds, components, and other devices. It comes with a long flexible shaft that typically comes in 12″ or 18″ but custom size options are availabl

FM-25

The FM-25 stainless steel tubing facing tool series is rugged and dependable, while consistently producing the cleanest and flattest surface to align and weld. Works with 1/8″ – 1″ OD Tube

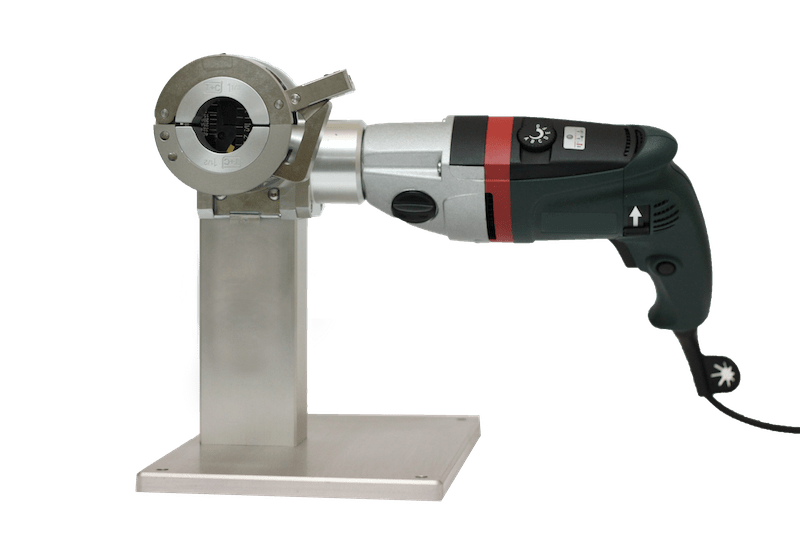

FM-63

Cut tube ranging from 1/4″ – 2.5″ with the electric FM-63. Standard aluminum collets allow for facing 3/4″, 1″ 1.5″ and 2″ tube. Mount it to a bench or bring it to your workpiece for quick squared faces.

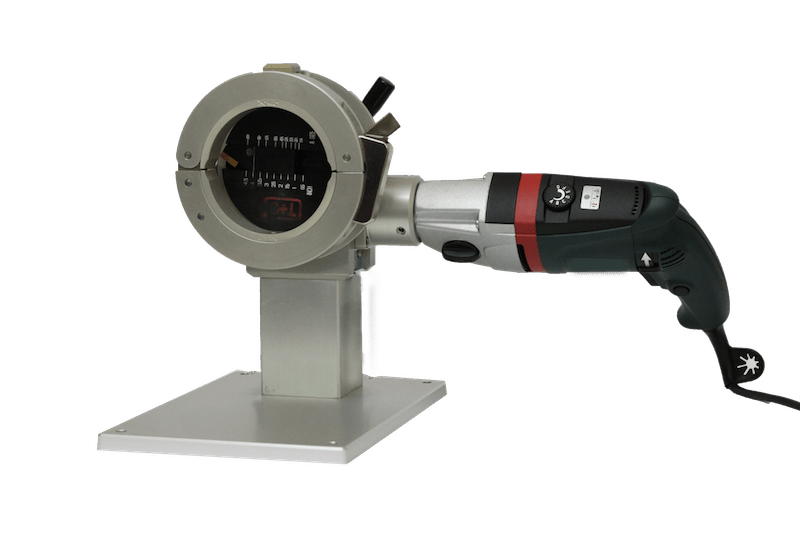

FM-114

T+C’s most versatile facing tool. Easily control speed and pressure with the electric motor and clamping kit. Face stainless steel, carbon, titanium, and most Nickle-based alloys in under 30 seconds.

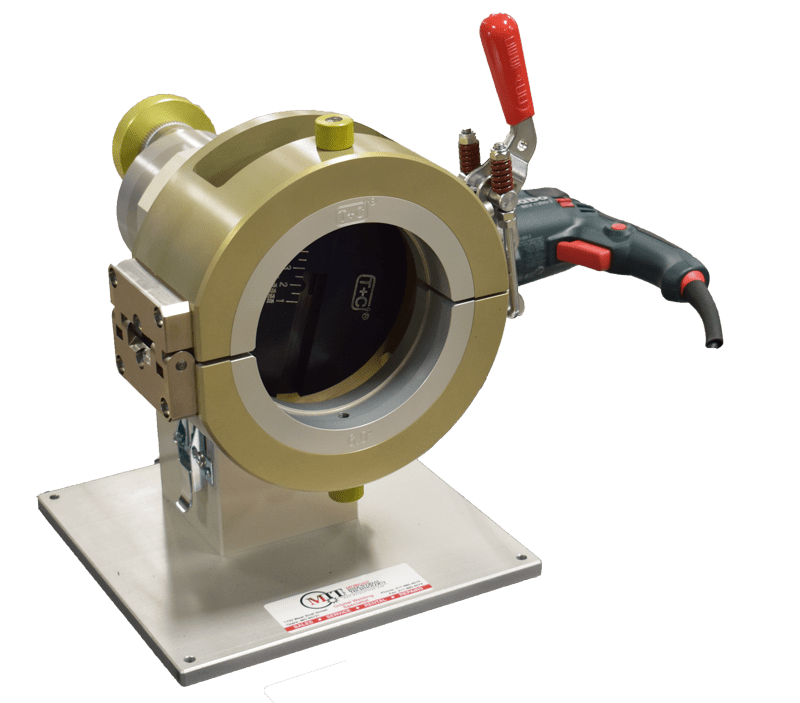

FM-168

Quickly clamp tubes up to 6.625″ into place on the FM-168. Portable or Bench Mounted, the FM-168 tube facer makes it easy for operators to get a squared finish on their workpiece.